Innovative clipping technologies

The production of original CLIPSAR® clips relies on proprietary technologies, backed by over 20 years of experience.

Our goal is to reduce the wear and tear on consumable parts of the clipping machine, including the matrix, punch, and clip guide. Regular use of the CLIPSAR® clips helps reduce waste caused by breaking sausage links.

We deliver smart solutions – intelligent solutions! . We deliver CLIPSAR®

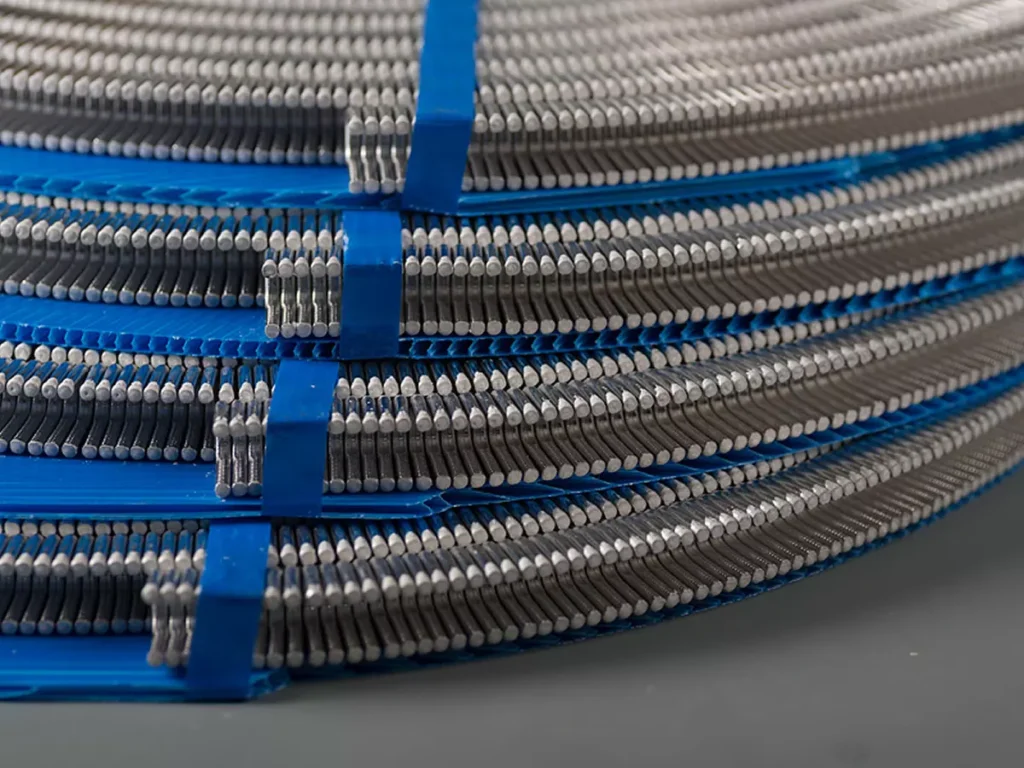

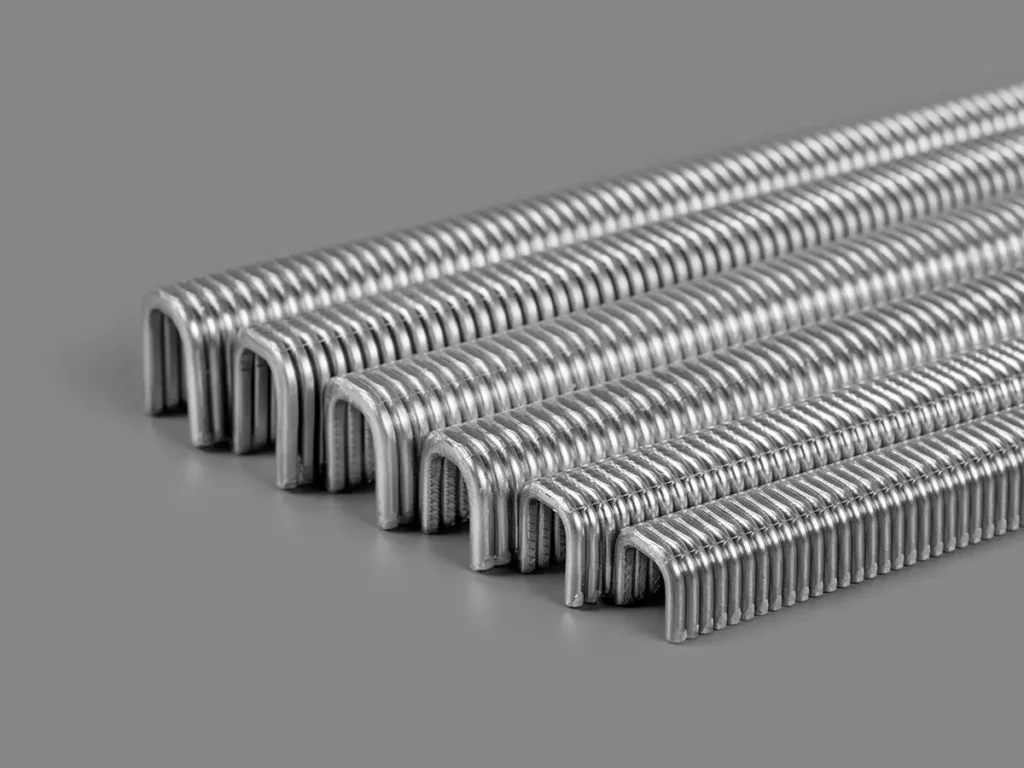

CLIPSAR® clips for automatic clipping machines

CLIPSAR® clips for automatic clipping machines are the result of years of research and development carried out by PROBITECH. Their innovation and quality were recognized in 2019 with the prestigious INNOVATIVE PRODUCT award.

What sets CLIPSAR® apart from standard clips are four innovative features that, when used consistently, enhance the casing sealing process, reduce production costs, and minimize waste.

Innovative technologies of the original CLIPSAR® clips on rolls

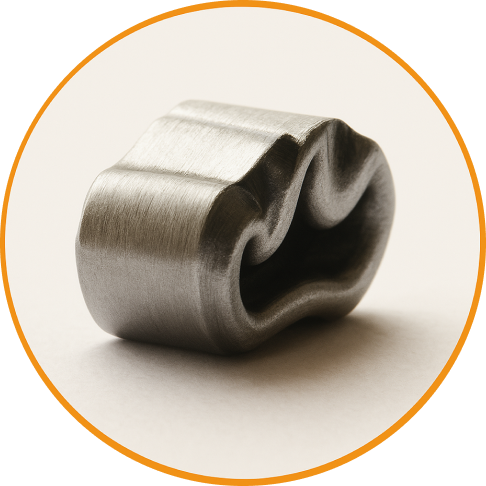

SLIM-END

the clip has no sharp edges that could damage the casings during the clipping and thermal processing stages of production.

SLIM-END

the clip has no sharp edges that could damage the casings during the clipping and thermal processing stages of production.

FLEXIBILITY

a reduction in the clipping force by up to 40% while ensuring a secure seal. This decreases the strain associated with the operation of the clipping machine.

FLEXIBILITY

a reduction in the clipping force by up to 40% while ensuring a secure seal. This decreases the strain associated with the operation of the clipping machine.

SAFE-INSIDE

the oil coating reduces dry friction in the clip guide, allowing the clip to position more easily in the die and ensuring a safer crimp of the clip on the casing.

SAFE-INSIDE

the oil coating reduces dry friction in the clip guide, allowing the clip to position more easily in the die and ensuring a safer crimp of the clip on the casing.

ZIP-CLOSE

the internal special engraving on the clip improves its grip on the casing, preventing the clip from slipping off the casing during the thermal processing of the sausage.

ZIP-CLOSE

the internal special engraving on the clip improves its grip on the casing, preventing the clip from slipping off the casing during the thermal processing of the sausage.

We produce clips for automatic clipping machines:

-

- 15/06 4×1,25; 15/06 5×1,25; 15/06 5×1,50; 15/06 5×1,75

- 15/07 4×1,25; 15/07 5×1,50; 15/07 5×1,75

- 15/08 5×1,50; 15/08 5×1,75

- 15/09 5×1,50; 15/09 5×1,75; 15/09 5×2,00

- 15/10 5×2,00; 15/10 5×2,20

-

- 18/07 5×1,50; 18/07 5×1,75

- 18/08 5×1,75; 18/08 5×2,00

- 18/09 5×1,75; 18/09 5×2,00

- 18/10 5×2,00; 18/10 5×2,20

- 18/11 5×2,00; 18/11 5×2,20

- 18/12 5×2,20; 18/12 5×2,50

- 18/13 5×2,50

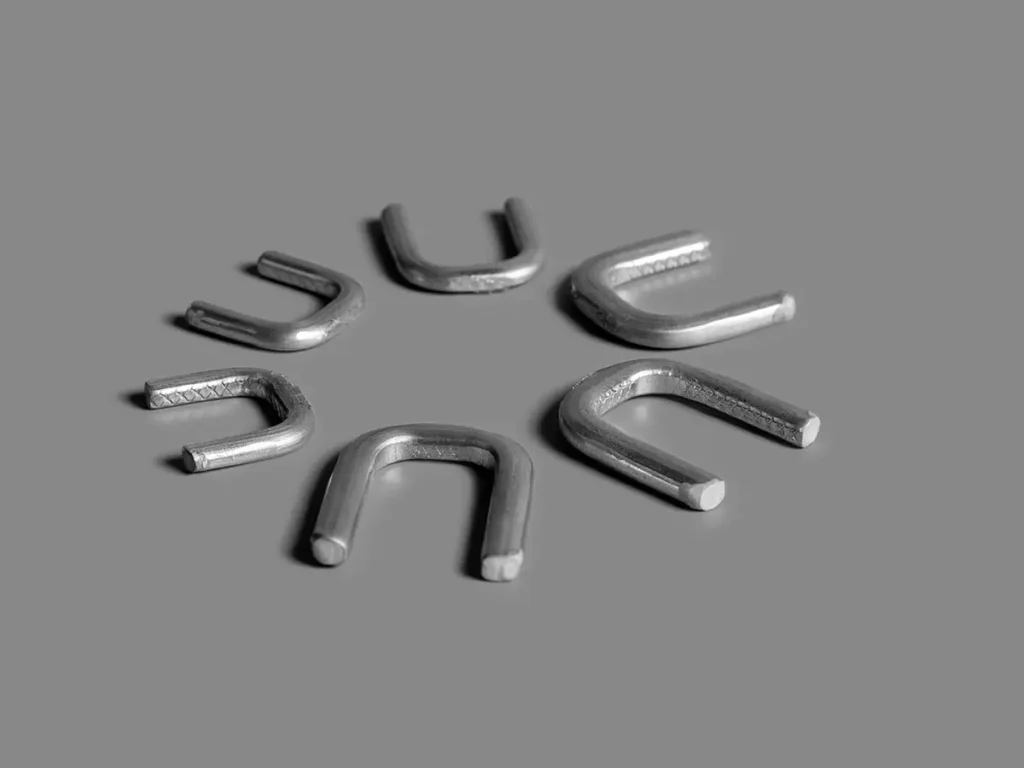

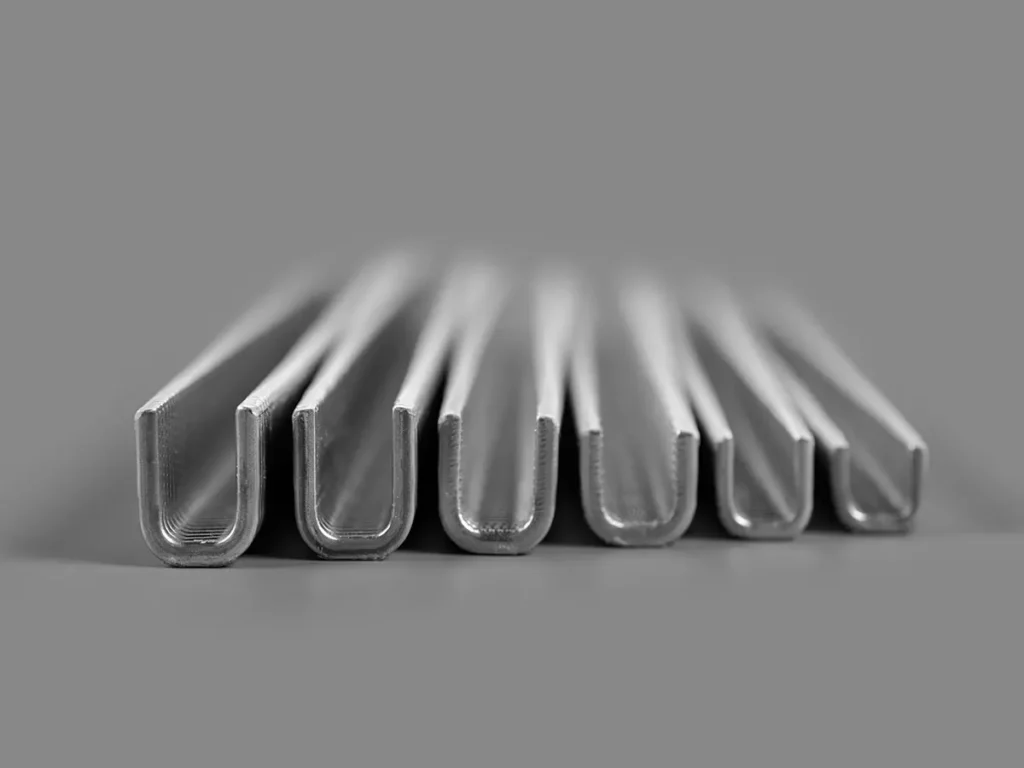

CLIPSAR® clips for tabletop and semi-automatic clipping machines

CLIPSAR® clips, named after their shape – “U-shaped,” are produced using Polish materials from certified suppliers. The aluminium wire has a purity grade of 99.7%, free from impurities, grease, and dust.

The clips are reliable, safe, and consistent. Their regular use helps reduce the wear on the matrix and punches. CLIPSAR® solutions feature a unique internal engraving on the clip, which improves the grip on the casing.

We manufacture clips from the following series:

- S628; S632

- S735; S740; S744

- S8735; S8740; S8744

- E210; E220; E230; E240

- G175; G200; G250

- G370; G390; G400

- K75; K100; K120

Advantages of Original CLIPSAR® Clips

PROFITABILITY

Up to 75% increase in profitability in the clipping process

DURABILITY

Up to 45% longer lifespan of consumable parts in clipping machines

SAFETY

Up to 25% improvement in product safety and protection when sealed with CLIPSAR® clips

AUTOMATION

No additional machine adjustments required for clips and loops

CLEANLINESS

Clips are free from dirt, dust, and harmful substances

CERTIFICATION

All raw materials used in production are sourced exclusively from certified suppliers