specialized cutting tools

Meat grinders, bowl cutters, and emulsifiers are essential machines in the meat processing industry. To operate effectively, they require reliable cutting tool sets. We provide specialized tools, distinguished by their unique features and technical specifications.

Our goal is for each SILCUT® set to grind meat better, more efficiently, and faster than any other standard tools on the market.

SILCUT® tools for meat grinders and cutters are innovative solutions that, to this day, have no superior counterparts in terms of design, execution, and materials used.

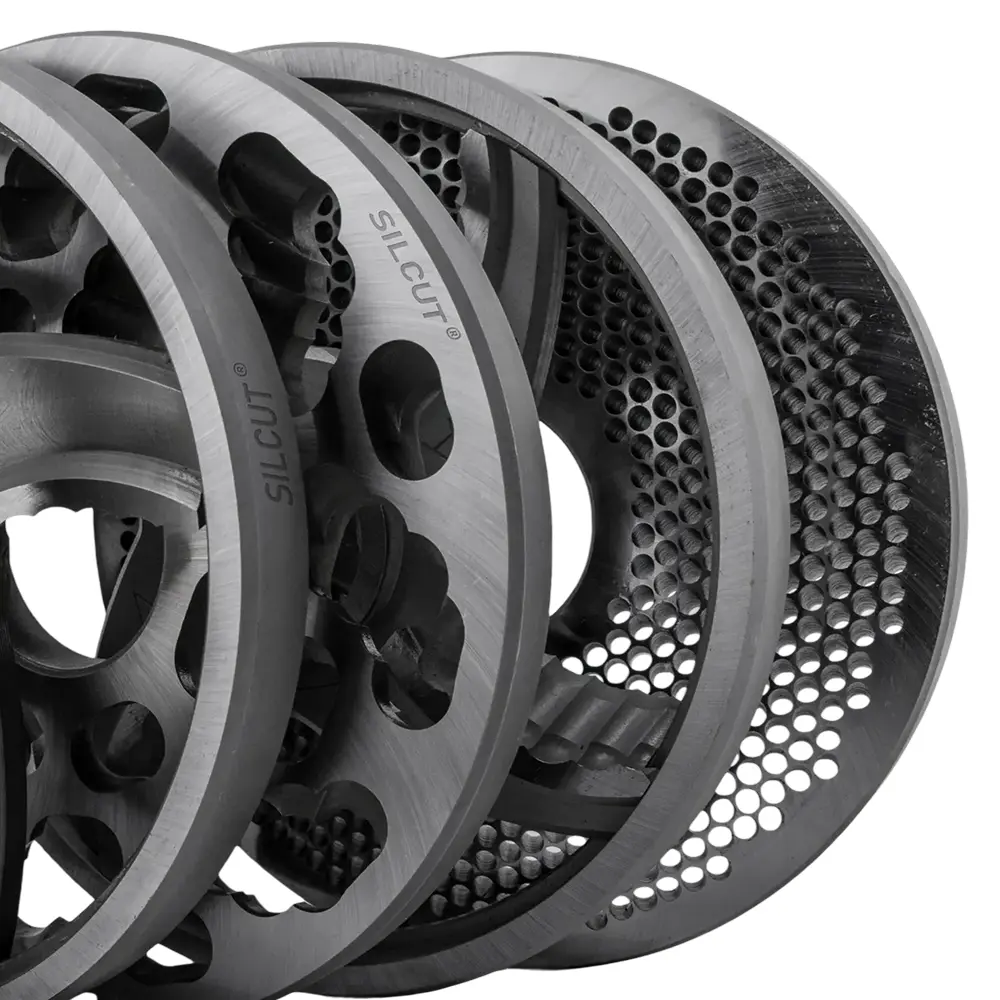

SILCUT® specialized tools for meat grinders

SILCUT® sets are compatible with machines from all leading brands. Made from high-quality steel, they are available in diameters ranging from 130-450mm, and are ideal for grinding both frozen and fresh meats.

The uniqueness of the SILCUT® set lies in its specially developed geometry and design for each individual component. These are entirely proprietary solutions that, in terms of design, execution, and materials, have no superior counterparts.

To achieve the full intended benefits of SILCUT® , we recommend using the complete set.

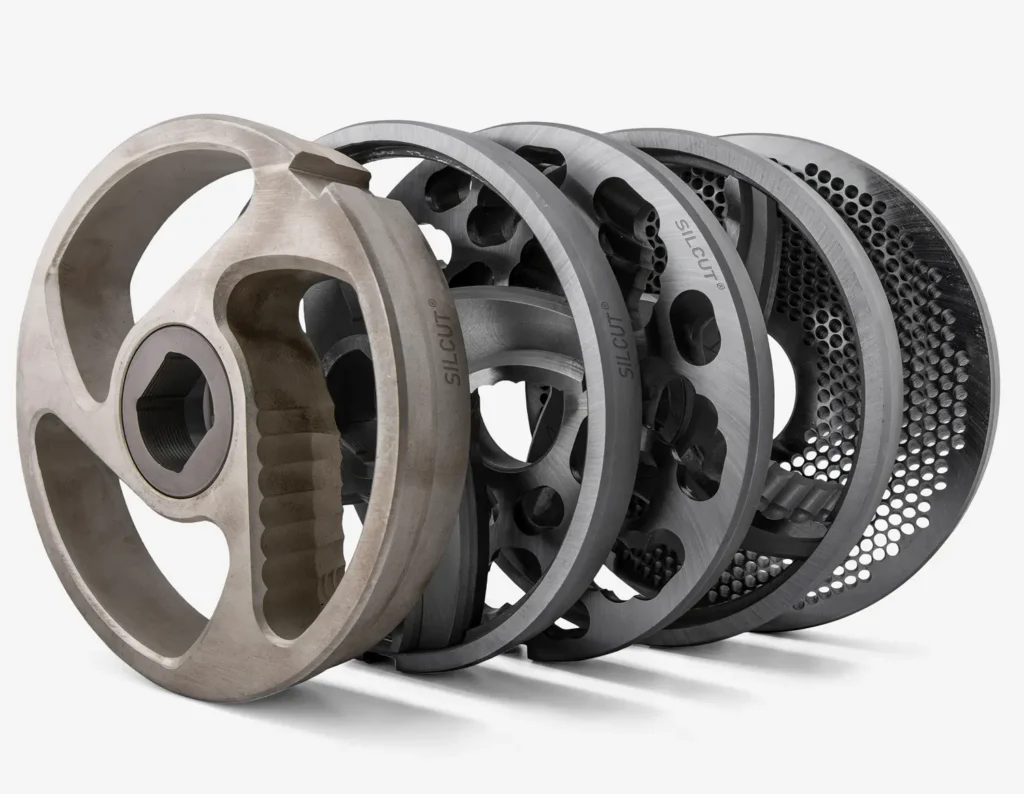

A single set of SILCUT® cutting tools for W200 meat grinders

PRE-CUTTER

The holes are kidney-shaped, featuring a unique cutting edge and grooved surfaces.

PRE-CUTTER

The holes are kidney-shaped, featuring a unique cutting edge and grooved surfaces.

KNIFE IN A RING

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

KNIFE IN A RING

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

ANGLE SIEVE

ANGLE SIEVE

Holes are made at a 20° angle, with displacement across the entire perimeter.

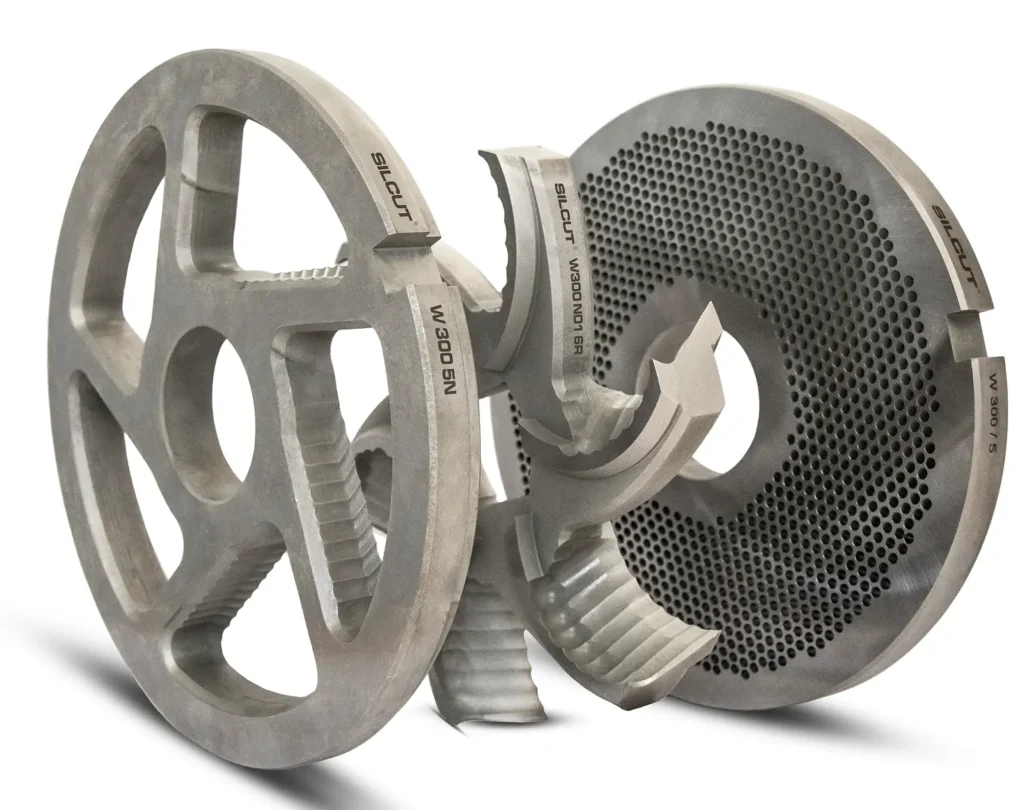

A double set of SILCUT® cutting tools for W200 meat grinders

PRE-CUTTER

The holes are

kidney-shaped, featuring a unique cutting edge and grooved surfaces.

PRE-CUTTER

The holes are

kidney-shaped, featuring a unique cutting edge and grooved surfaces.

KNIFE IN A RING “A”

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

KNIFE IN A RING “A”

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

SPECIAL SIEVE

Specialized curved geometry of the knife arms, with a unique cutting edge and grooved surfaces.

SPECIAL SIEVE

Specialized curved geometry of the knife arms, with a unique cutting edge and grooved surfaces.

KNIFE IN A RING “B”

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

KNIFE IN A RING “B”

A set of holes with a special geometry, featuring a unique cutting edge and grooved surfaces.

ANGLE SIEVE

Holes are made at a 20° angle, with displacement across the entire perimeter.

ANGLE SIEVE

Holes are made at a 20° angle, with displacement across the entire perimeter.

Compared to standard cutting sets, SILCUT® tools offer

EFFICIENCY

Increased productivity and efficiency by up to 30%

TEMPERATURE

Lower meat processing temperature

CUTTING

Clean cut effect – muscles are sliced rather than crushed

SHARPNESS

Extended tool life – up to 120% longer before the next sharpening is needed

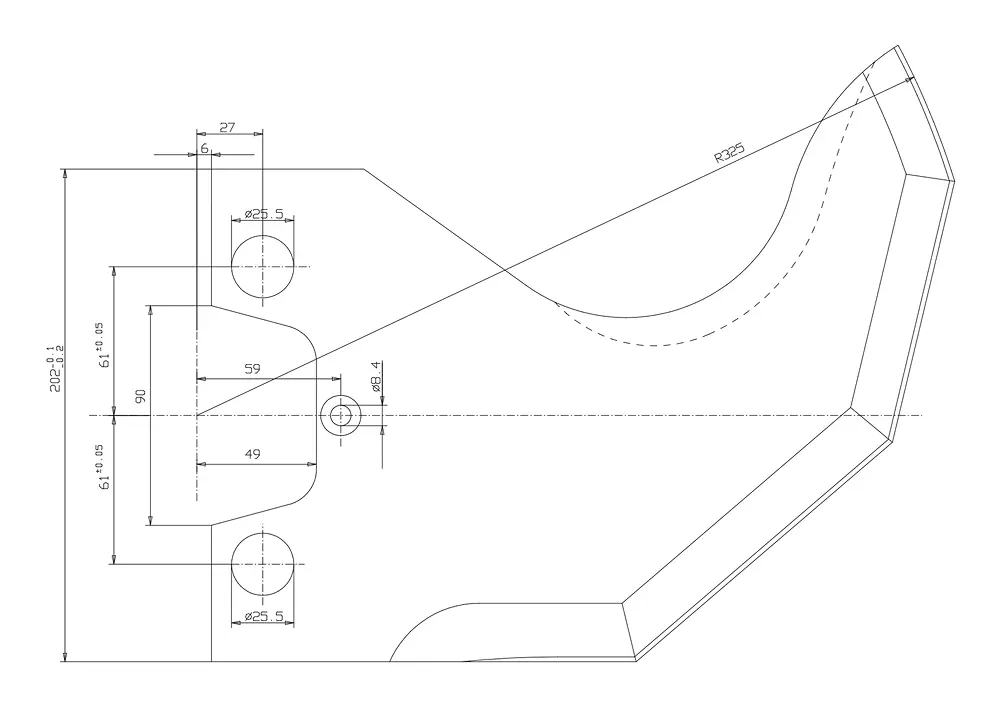

SILCUT® specialized knives for bowl cutters

High-quality knives for meat bowl cutters, compatible with machines from all leading brands ensure easy installation and use. Made from stainless steel, acid-resistant steel, or other high-grade materials. Available in various types, sizes, and shapes to meet specific requirements.

SILCUT® knives for bowl cutters stand out due their proprietary design and geometry solutions, combined with a unique hardening process that employs an innovative multi-stage hardening method.This results in exceptional performance — SILCUT® knives are extremely durable, highly resistant to cracking, and require sharpening far less frequently than standard knives.

Working with SILCUT® sets ensures high precision in meat grinding and enhanced heat dissipation during operation – both contributing significantly to increased productivity and efficiency.

Compared to standard knives for bowl cutters, SILCUT® tools offer

EFFICIENCY

Increased productivity and efficiency by up to 30%

DRAINAGE

Improved heat dissipation

TEMPERATURE

Lower meat processing temperature

DURABILITY

Enhanced knife durability

RESISTANCE

High resistance to cracking

SHARPNESS

Extended tool life – up to 120% longer before the next sharpening is needed